How To Use RFID Tags

Shipping, transportation, receiving, and monitoring are all integral components of the larger supply chain. Being responsible for the safety and security of cargo comes with quite a few challenges. The present surge in demand for supplies coupled with clogged ports and warehouse labor concerns has made the challenge of shipping things considerably greater. And those issues are on top of the more practical concerns of safely shipping cargo: temperature, impact monitoring, tracking, and monitoring. Applying a technological solution is a favorable, pragmatic course of action that can take some of the edge off of the day-to-day challenges inherent in logistics, streamlining operations, and rendering the process as smooth as possible. RFID tags offer a long-term, simple solution that can help you. But what are they? What do they do? And more importantly, how do you use them? In this article, we’ll answer those questions and more. Check it out below.

Table of Contents

What RFID Tags Do

RFID Tags are a system of “intelligent” tags that are used in everything from shipping to checking out library books. They are essential to inventory control and so many other things. numbers or data. Some also have built-in security features that assist with authentication. RFID tags can run the gamut between low frequency (range between 30 – 300 kHz), high frequency (range between 3 and 30 MHz), and ultra-high frequency (UHF, ranging between 300 MHz and 3 GHz). UHF tags can be read from longer distances than the other two. UHF tags are often incorporated into garage doors, inventory tracking systems, asset management, and much more. One might find RFID technology implemented into payment systems (high-frequency RFID is ideally suited to this) or even shopping security/theft prevention systems. Low-frequency RFID is useful, too, for some applications. In most RFID asset tracking situations, you’ll have the tags themselves along with a few other components to complete the package. There will likely be a reader of some kind, either handheld or via a smart device.

Understanding RFID

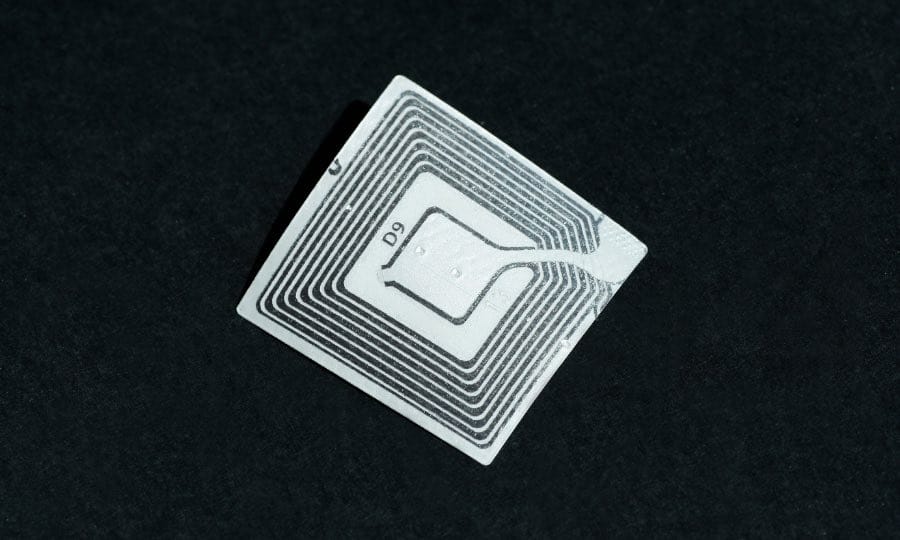

RFID stands for “radio frequency identification.” RFID is used in numerous applications across several unique industries and disciplines. What makes it so versatile is how it can be used in tags to monitor and track cargo during transit. Think of an RFID tag as a sort of “smart” label. It can contain certain types of information, such as serial numbers or data. RFID is not the same as a barcode. Barcodes require a direct line of sight for scanning and need to be in close proximity to the reader. This is not the case with RFID, as readers can scan items from a few inches or feet away. Furthermore, data updates happen fast (often in real-time) and it only takes a few milliseconds to read data from the tag. With a barcode, you’re looking at half a second or more. The typical construction of an RFID tag or system involves an antenna (usually in the back of a tag), a transceiver, and a transponder. The antenna (a scanning antenna) and transceiver combine into a single device known as the reader/interrogator. A transponder, nestled within the RFID tag itself, is responsible for the signal. There are three types of RFID tags: passive, semi-passive, and active. Here’s a quick breakdown of each:

Passive RFID Tags

Passive RFID tags are ideal for supply chain monitoring, cargo monitoring, and asset tracking. It’s likely to find these tags across numerous industries. Hospital safety is a vital application for passive RFID tags. To increase safety and security, hospitals can use RFID tags to prevent unauthorized access to off-limits areas of the hospital. It can also reduce labor tracking with hospital logistics. Locating scrubs, linens, and key medical equipment with passive RFID tags is only one of the many ways these tags are utilized in real-life situations. They can be quite useful for parking lot scanning gates, inventory control, tracking tools, and checking for impacts along a supply chain.

Active

Active RFID tags use a battery to allow the transmitter to constantly send and receive data. Active tags are ideal for large-scale industrial use. They’re also bigger than passive tags and typically have longer readable ranges. They’re perfect for construction, mining, and manufacturing due to their long-range and powerful sending/receiving capabilities.

Semi-Passive

These tags are sometimes referred to as battery-assisted passive tags (BAP) because they’re a type of passive tag that requires a power source. The battery helps to extend the communication range. These tags might also contain sensors. They’re used often for file tracking and small or mid-sized applications.

Why Adopt Them

Making the case for adopting RFID tags at your operation is fairly straightforward: they can make the process of assessing and logging damage—whether it’s from impacts or mishandling—much simpler. When you implement comprehensive RFID asset tracking into your supply chain operations, you’re making a commitment to the quality and protection of your goods. Without as many shipping issues, delays, damage, theft, or other myriad problems, your business will thrive. Instead of disappointing customers, you’ll garner a better reputation over time—all because you saw the value in implementing RFID tracking tools. RFID tags are easy to use, with no learning curve at all. They just need to be placed inside or outside the package/cargo and then checked/read as appropriate. Compliance standards are also in place to ensure exceptional quality and high functioning of the technology. RFID tags are a quite safe and multifaceted technology. RFID must also conform to specific standards, as outlined by the International Organization for Standardization (ISO), Electronics Product Code Global Incorporated (EPCglobal), International Electrotechnical Commission (IEC). Compliance standards are in place to protect the public and users while also reinforcing the quality of the technology.

Damage Prevention and Theft Prevention

Spotting damage is one thing, but using RFID tags helps attenuate it and informs the development of a prevention plan. Using RFID tags reduces damage and potential damage by a whopping 40-60% overall. That’s a pretty big deal when you’re talking about moving large quantities of supplies across the entire chain. Less damage translates into fewer delays. Delays can be a significant problem because they create shortages of everything. From vehicles to basic needs, delays prevent critical supplies from reaching their destinations. Supply issues not meeting demands creates shortages. Depending on the industry, this can be catastrophic (think pharmaceuticals and vaccines) or simply annoying (when the store is out of your favorite cookies). RFID tags are also extremely useful for preventing theft and loss of cargo. RFID tags used in supply chain management and logistics are designed to be robust. They’re tamperproof and act as a visual deterrent for anyone looking to steal or cause trouble. Moreover, they can be used in so many applications and industries, there’s really no limit to the benefits RFID asset tracking can provide.

Remote Reading

One of the more appealing aspects of using RFID technology for asset tracking is the ability to read them remotely, without a direct line of sight to the tag. This means you can use the reader to scan the tag, then check out the information through an app or other interface that interacts with the reader. What makes it so convenient is that, unlike bar or QR codes, it’s possible to remotely read RFID tags. The issue of line of sight—a minor inconvenience of using other types of technology for this purpose—is not required for RFID! The distance at which you can read a tag varies by its frequency. Obviously, you won’t be reading tags while cargo is in transit. Instead, the time to read and examine them is after they reach a destination or checkpoint. This gives logistics managers plenty of flexibility for reading, checking, monitoring, and replacing their RFID tags.